Development

In-house

Thanks to state-of-the-art equipment and measuring instruments, we are able to independently and flexibly develop customised solutions and adapt them to the respective requirements.Our in-house department develops new systems and innovations for the digitalisation of railway infrastructure so that W&S Technik can make the future better today. Dank modernsten Equipment und Messinstrumenten sind wir in der Lage, unabhängig und flexibel, individuelle Lösungen zu entwickeln und diese an die jeweiligen Bedürfnisse anzupassen. Precise engineering, customised software solutions and efficient hardware design are already making W&S a self-sufficient company of the future.

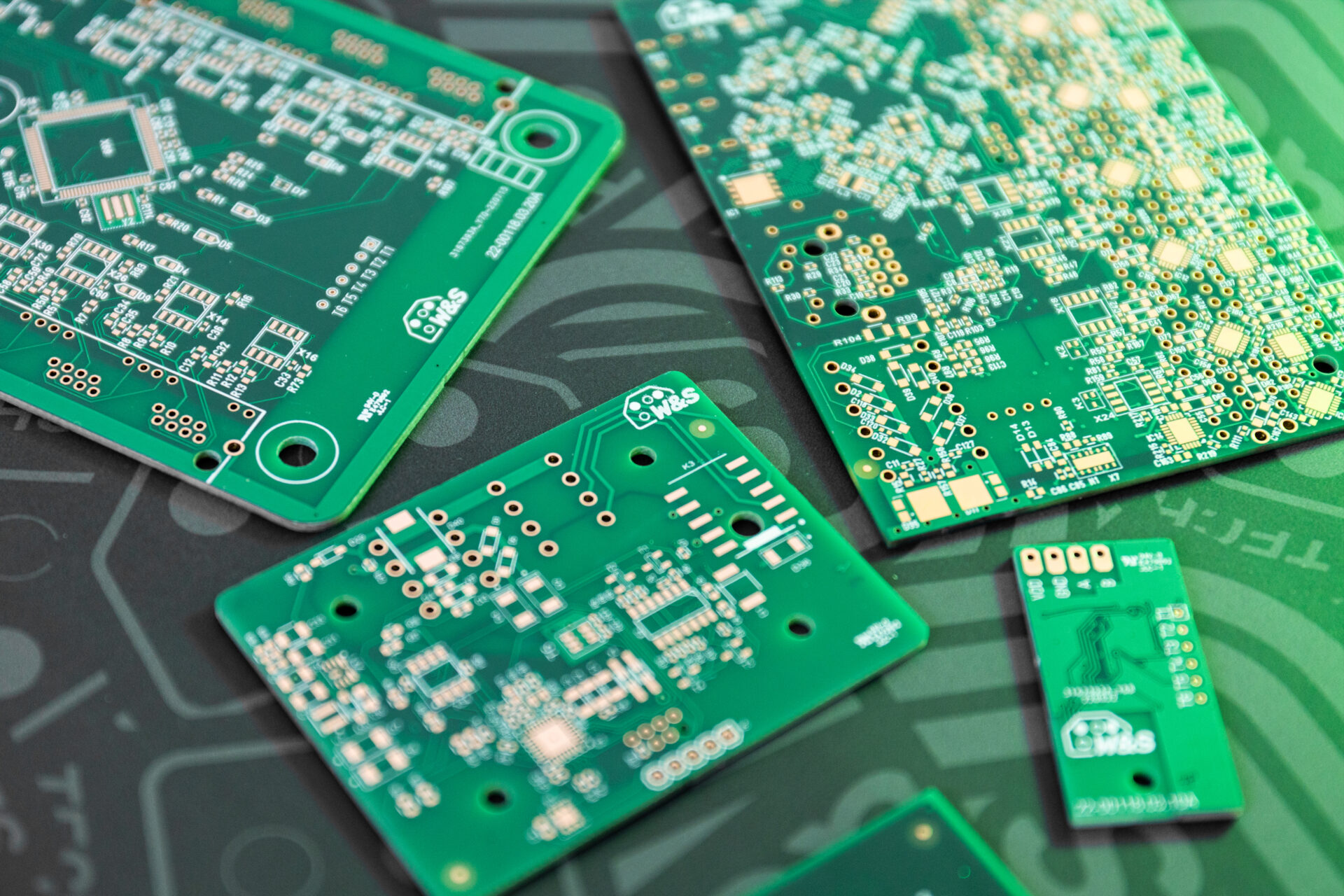

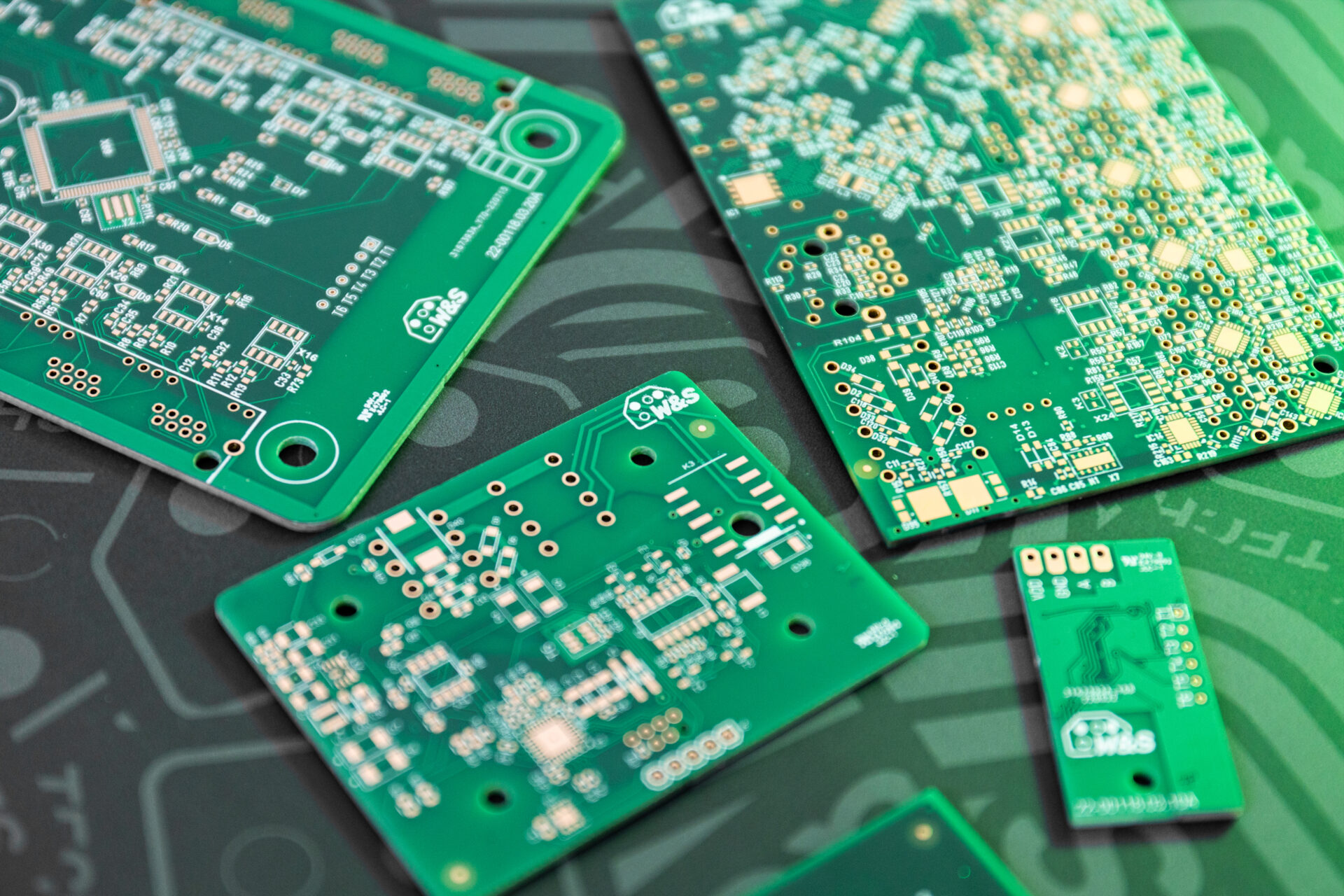

Hardware development

Our in-house development department covers both software and hardware development. We specialise in the creation of circuit diagrams and PCB layouts in order to develop customised solutions for our systems. By closely linking software and hardware, we are able to offer integrated solutions that fulfil our customers’ requirements. We use advanced tools to optimise the development process and ensure efficient collaboration between the teams. Our holistic approach enables us to develop innovative and customisable monitoring systems for the railway.

Our overall aim is to create high-quality preventive monitoring systems that are both technically sophisticated and reliable. By combining software and hardware development, we ensure that our systems function smoothly and meet high quality standards.

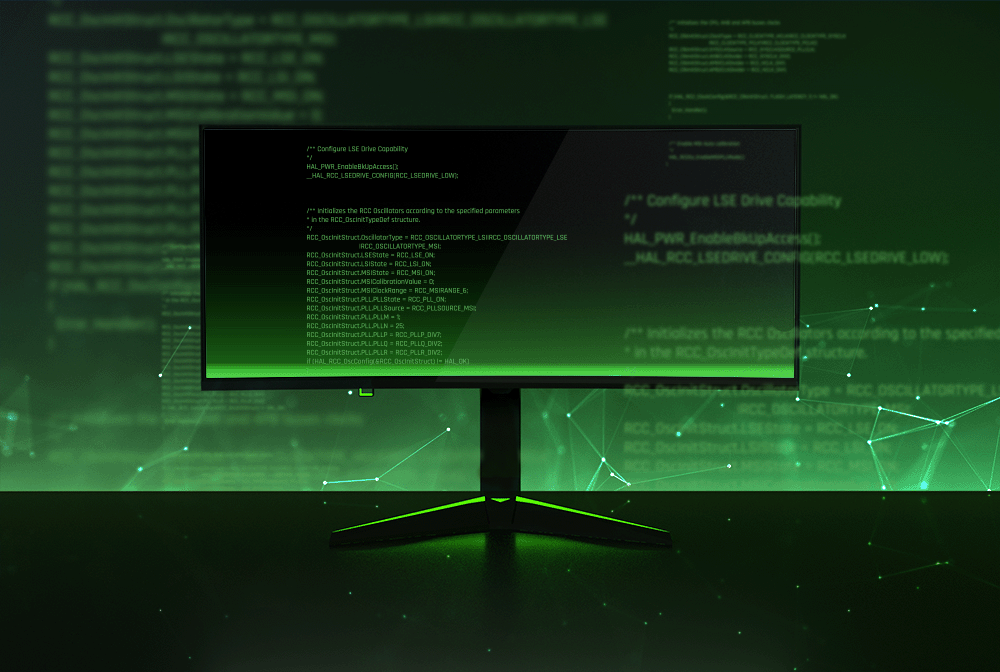

Software development

Our in-house development department specialises in the development of efficient software for preventive monitoring systems in cable infrastructure in the field of control and safety technology. We have expertise in C#, .NET, Windows Forms and common database standards. We are also interface experts and are familiar with communication protocols such as Modbus RTU, CAN, I2C, SPI and UART. We are also interface experts and are familiar with communication protocols such as Modbus RTU, CAN, I2C, SPI and UART. For our development work, we use advanced environments that help us to create efficient software solutions.

We attach great importance to innovation, efficiency and high quality standards. Our expertise in these areas enables us to develop customised preventive monitoring systems for cable infrastructure that are reliable, powerful and meet the individual requirements of our customers.

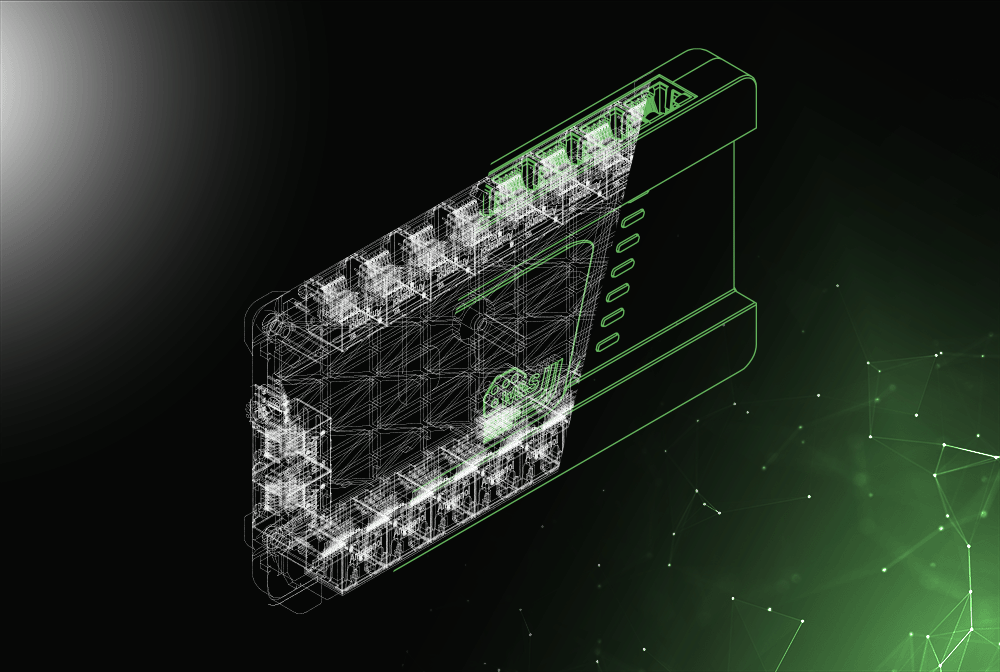

Prototypes

Made to measure

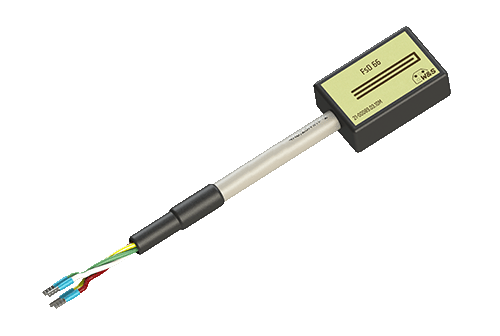

From efficient design and precise part production with FDM/SLS 3D printers to customised hardware and software solutions, we are able to develop professional prototypes flexibly and independently from the very first moment. Each project is rounded off with subsequent measurement and load tests as well as professionally prepared documentation and records. This enables us to offer all services from your idea to the customised product from a single source.

Hardware development

Our in-house development department covers both software and hardware development. We specialise in the creation of circuit diagrams and PCB layouts in order to develop customised solutions for our systems. By closely linking software and hardware, we are able to offer integrated solutions that fulfil our customers’ requirements. We use advanced tools to optimise the development process and ensure efficient collaboration between the teams. Our holistic approach enables us to develop innovative and customisable monitoring systems for the railway.

Our overall aim is to create high-quality preventive monitoring systems that are both technically sophisticated and reliable. By combining software and hardware development, we ensure that our systems function smoothly and meet high quality standards.

Software development

Our in-house development department specialises in the development of efficient software for preventive monitoring systems in cable infrastructure in the field of control and safety technology. We have expertise in C#, .NET, Windows Forms and common database standards. We are also interface experts and are familiar with communication protocols such as Modbus RTU, CAN, I2C, SPI and UART. We are also interface experts and are familiar with communication protocols such as Modbus RTU, CAN, I2C, SPI and UART. For our development work, we use advanced environments that help us to create efficient software solutions.

We attach great importance to innovation, efficiency and high quality standards. Our expertise in these areas enables us to develop customised preventive monitoring systems for cable infrastructure that are reliable, powerful and meet the individual requirements of our customers.

Prototypes – ready to measure

From efficient design and precise part production with FDM/SLS 3D printers to customised hardware and software solutions, we are able to develop professional prototypes flexibly and independently from the very first moment. Each project is rounded off with subsequent measurement and load tests as well as professionally prepared documentation and records. This enables us to offer all services from your idea to the customised product from a single source.

Prototype development – from the brilliant idea to the finished product

Design

3D-print

Hardware

Software/Firmware

Test

Put through its paces

To ensure that our components and systems meet the highest quality standards, we put them through thorough testing and extensive measurements. To ensure that our components and systems meet the highest quality standards, we put them through thorough testing and extensive measurements. Our procedures include a variety of tests in which we put all aspects of our components and systems through their paces. From electrical performance and response to different conditions to long-term stability – we ensure that every element meets our strict quality requirements and standards such as DIN EN 61000, DIN EN 50121 or DIN EN 50125. These comprehensive tests enable us to ensure that our customers receive products that they can rely on and that offer maximum performance and reliability.

Extensive range of state-of-the-art measurement technology

-

- Oszilloskope, Picoskope

- Spectrum Analyzer

- Function generators

Straining for the highest quality

-

- EMC tests in our in-house laboratory

- STANDARD IEC 61000-4-2, -4-4, -4-5

- Climate chamber with a temperature range from -70°C to +180°C

- Humidity control from 10% to 95%

Put through its paces

To ensure that our components and systems meet the highest quality standards, we put them through thorough testing and extensive measurements. To ensure that our components and systems meet the highest quality standards, we put them through thorough testing and extensive measurements. Our procedures include a variety of tests in which we put all aspects of our components and systems through their paces. From electrical performance and response to different conditions to long-term stability – we ensure that every element meets our strict quality requirements and standards such as DIN EN 61000, DIN EN 50121 or DIN EN 50125. These comprehensive tests enable us to ensure that our customers receive products that they can rely on and that offer maximum performance and reliability.

Our Equipment

Extensive range of state-of-the-art measurement technology

-

- Oszilloskope, Picoskope

- Spectrum Analyzer

- Function generators

Straining for the highest quality

-

- EMC tests in our in-house laboratory

- STANDARD IEC 61000-4-2, -4-4, -4-5

- Climate chamber with a temperature range from -70°C to +180°C

- Humidity control from 10% to 95%

And much more!